BellHawk Manufacturing

Vendor Managed Inventory

How a packaging manufacturer eliminated customers' stock-outs, reduced costs, and won more business

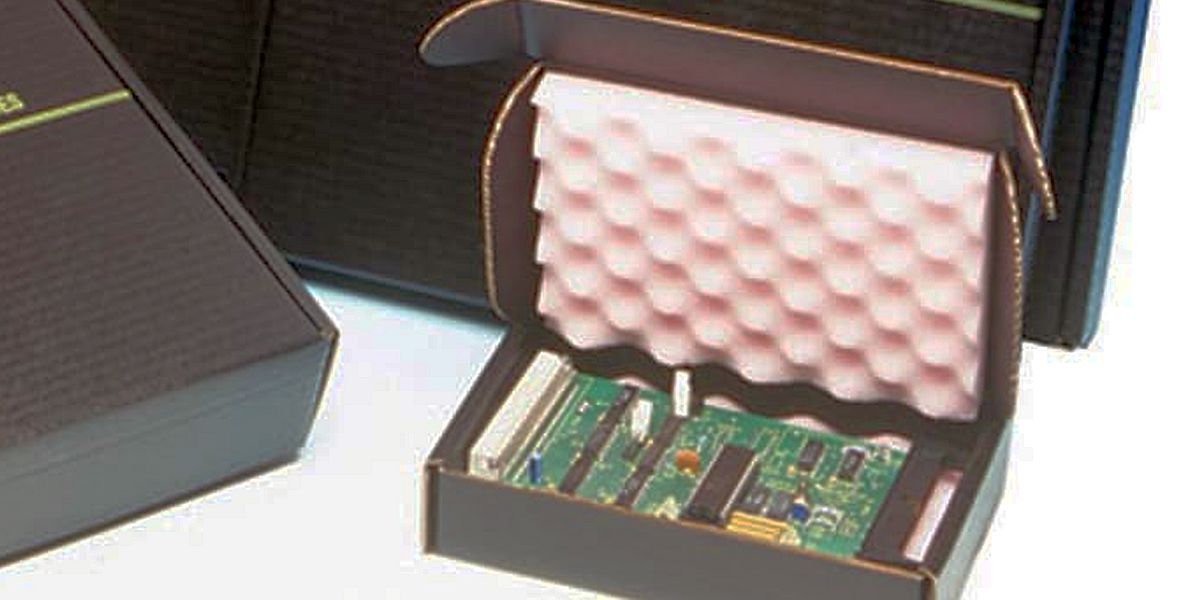

Suppliers of electronics pack products in corrugatedcardboard boxes with foam inserts. Image: GWP Pacakaging

This manufacturer makes and delivers custom corrugated cardboard boxes with foam inserts for packaging electronic equipment. These boxes were made to-order in relatively short runs to customer order.

Problems

- Customers would go out to at least three possible suppliers for competitive bids for every order, at high cost on all sides.

- Rock-bottom prices, with no allowance for quality, speed or reliability of delivery.

- Fluctuating demand for products and unreliable forecasts.

- Frequent stock-outs at customers delaying shipment of their products.

- Panic “fire drills” to deliver boxes disrupting production and especially delivery truck schedules.

Solution

To solve this problem the company decided to introduced a pull-based Vendor Managed Inventory system for their customers, based on the BellHawk softwares.

VMI Scheme

- The company and the customer agree max and min inventory levels for each type of box.

- The company produces enough skids of boxes to bring the inventory up to the maximum level.

- Each skid has a peel-off “license-plate” barcode label to identify the product and quantity on the skid.

- The company provides a barcode scanner for a PC as a “gift” for the customer to scan the labels on the skids as they use them.

VMI Process

- An operator scans the barcode label on the skid at the end of the production line to track it into the warehouse. It is scanned out of the warehouse when shipped to the customer.

- Each time the customer’s material handlers take a skid of boxes to their production floor they peel off the tracking label and stick it to a sheet of paper on a clipboard.

- Every night the customer’s warehouse manager picks up the clipboard and goes to a special BellHawk web portal to scan in the tracking barcodes on the sheet.

- The BellHawk software tracks how many boxes of each type are in stock at each customer's site and decrements the quantity as skids are used.

- When the quantity of a box at the customer site goes below the minimum level BellHawk generates a ship order to replenish the inventory.

- If the company does not have sufficient stock BellHawk generates a production order to make the requisite number of skids.

- BellHawk increments the quantity at the customer's site when the new skids are delivered.

Benefits

- Elimination stock-outs at the customer’s site.

- Customers eliminated the big overhead cost of competitive bids for each purchase of boxes.

- The company eliminated the cost of repeated bids for small repeat orders of custom boxes.

- The company was able custom build products just-in-time to meet actual customer demand rather than building to forecast and warehousing the surplus.

- The company and customers ran much leaner inventories, with just enough on hand to cover replenishment and delivery times.

Results

- The company's operation more efficient with far fewer boxes made for stock against forecast demand that never materialized.

- “Fire-drills” for stock outs were eliminated, resulting in much more efficient scheduling of delivery truck routes.

- The VMI service won significant new business with a competitive “lock-in” for their products.

Related Applications

Barcode tracking, automated labelling, expiry date control, and hazardous material logs

How a jeweller halved its stocks of precious metals and stones while improving deliveries

How a machinery manufacturer uses mobile terminals to pick spares for its global network