Quality • Safety • Trust

Codeway instigated the use of automatic identification technologies for food traceability through AIM UK (Automatic Identification Manufacturers association) over 20 years ago. In 1997 TAG UK (Traceability Action Group) brought beef farmers together with retailers and the ministry.

TAG UK's recommendations carried forward into the EU FoodTrace concerted action with GS1 which providded the technical basis for traceablity in the EU 2004 Food Directive. The EU 2008 Explosives Directive mandated an equivalent system for explosives with product serialisation.

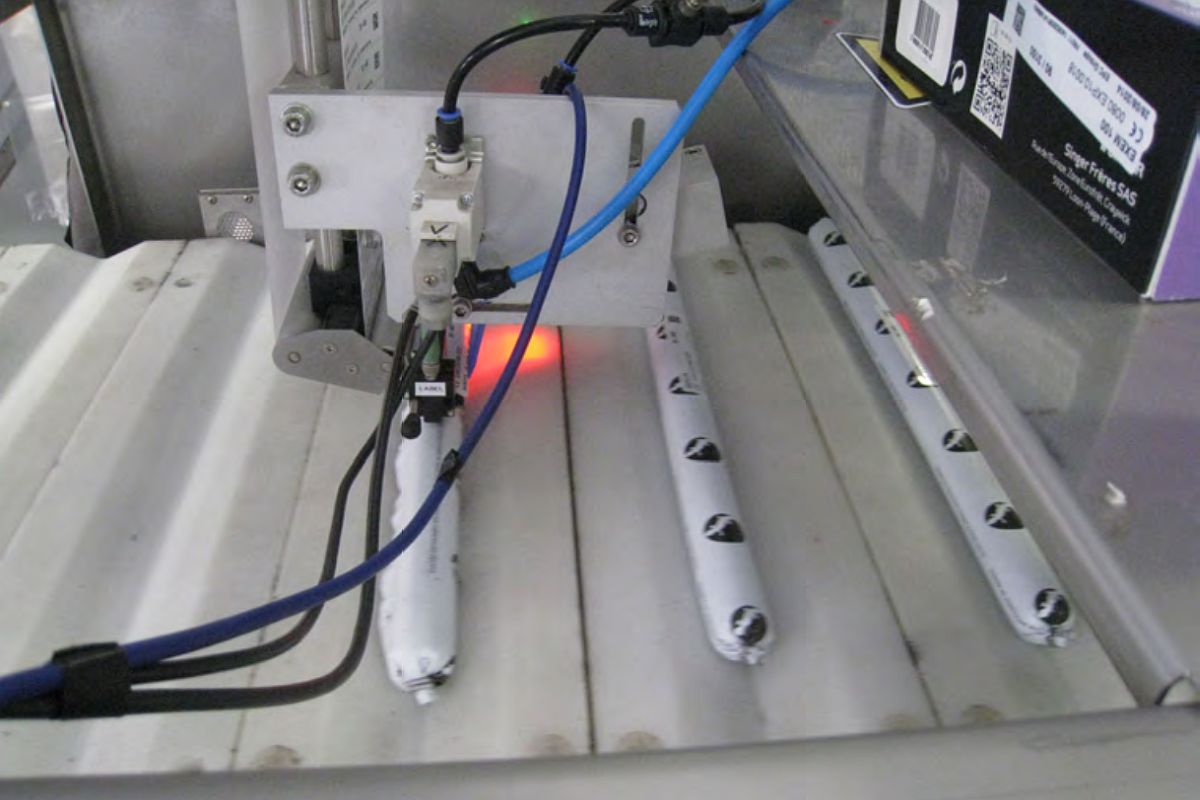

Traceability requires identification of batches and items and recording of their attributes. These batches and items must be tracked through each process often by scanning a barcode an RFID tags. All exceptions must be detected, handled and recorded, otherwise control and traceability will be lost.

IDENTIFY : TRACK : CONTROL

Traceability Systems

Traceability Online

• Monitors all materials in need of inspection

• Records all checks and proves compliance

• Prevents use or shipment of defective material

• Deliver what the customer ordered.

• Avoid mistakes with QC and ingredients.

• Be ready for a rapid recall.

• Control ingredients • Serialise products.

• Trace materials, mixes, products, packaging.

• Comply with GMP/FDA process standards,

• Maintain lot and serial number traceability

• Trace back to source and forward to customers

• Comply with GMP/FDA and other regulations

Winning Solutions

We will be delighted to recommend and supply the right products for your project. Codeway provides full technical services and lifetime support to ensure a great return on investment year after year.

Ask Codeway to quote for • Label printers • Labels • Scanners • Automated identification systems • Mobile computers • Application software • Technical services

When you need software to support your business operations, Codeway specialises in data capture, data exchange and tracking systems for production, distribution and services.