Oil rig safety chain

How a label became the final link in the North Sea oil safety chain after the Gulf of Mexico disaster

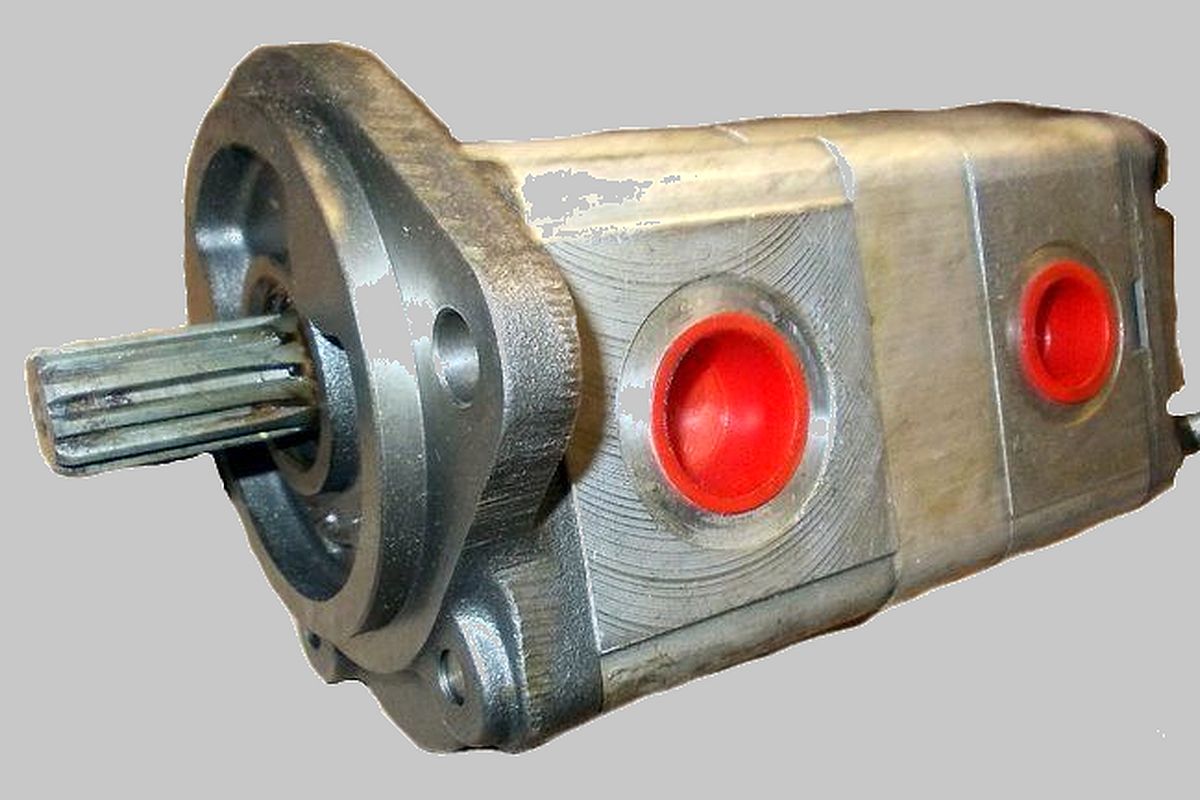

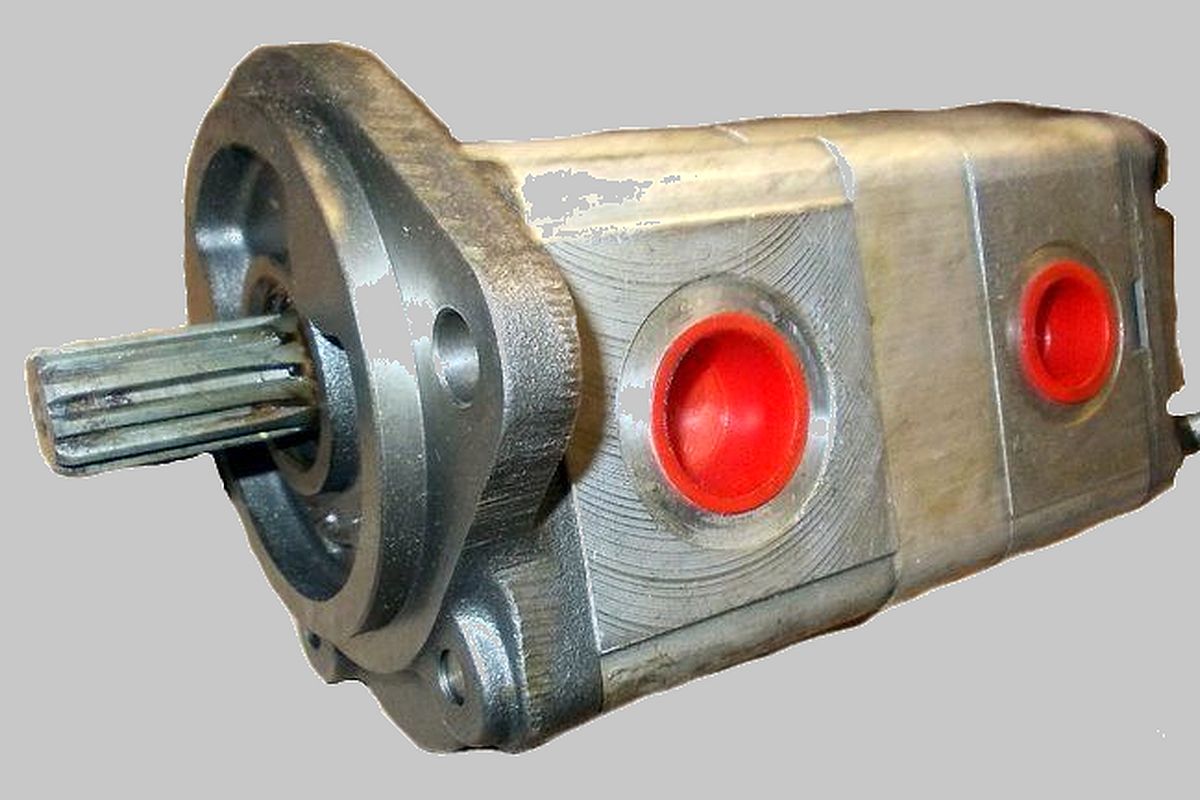

When a part fails the correct replacement must be fitted. How do you identify it? Without a label you can't.

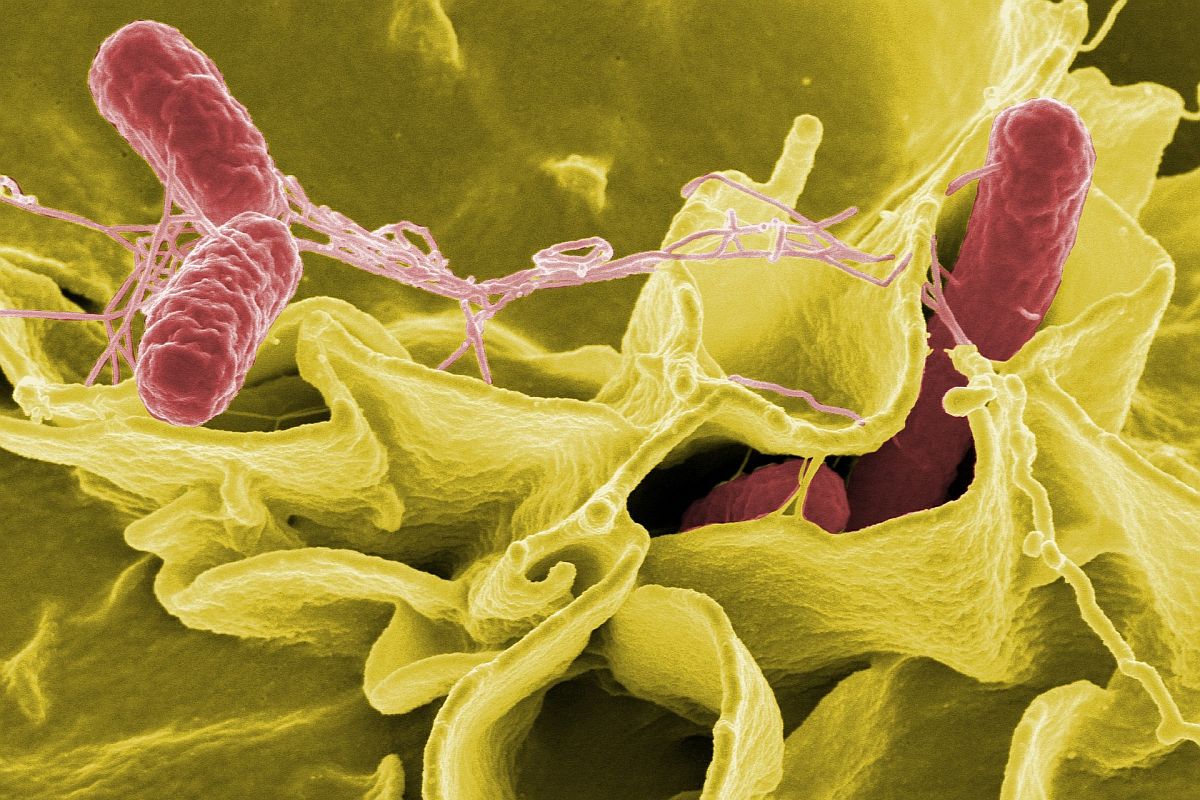

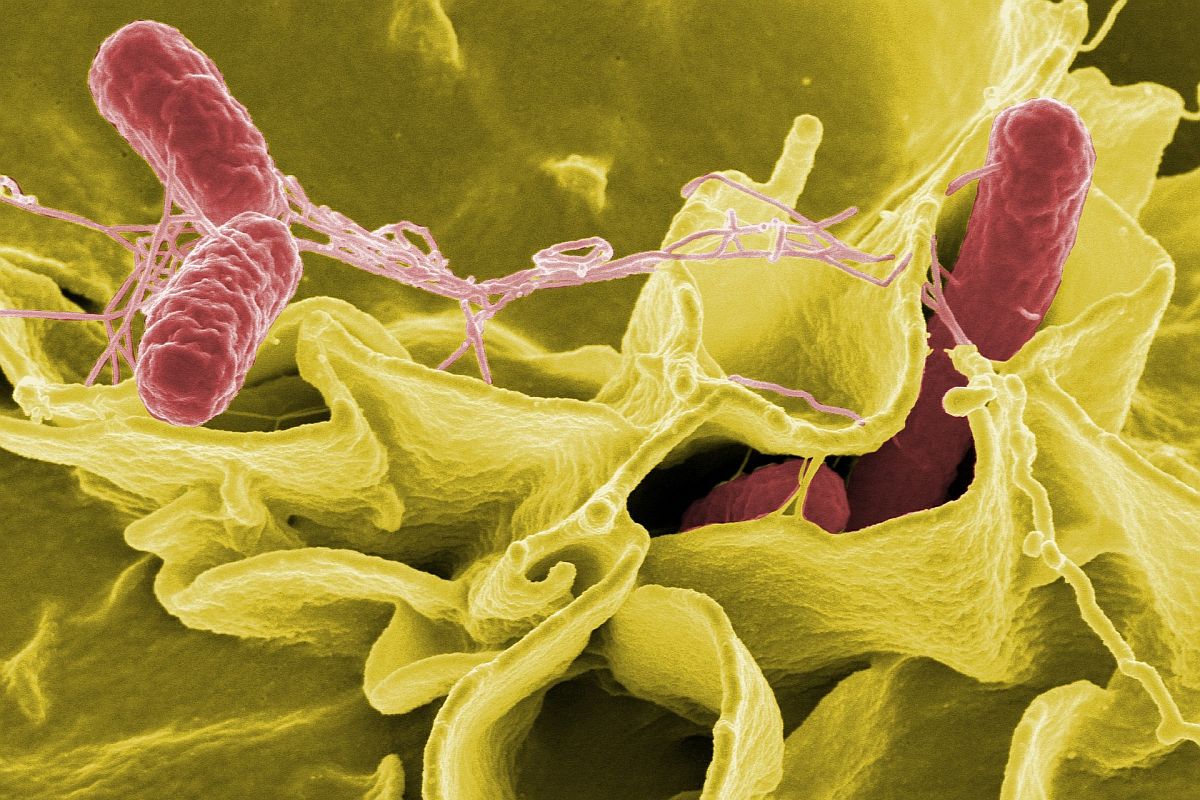

Explosion in the Gulf of Mexico

The Deepwater Horizon explosion on 20 April 2010 led to a root and branch review of safety systems in the oil industry.

In 2012 a leading global supplier of critical control and safety solutions contacted Codeway. Already a customer, they wanted system to print highly durable identification labels for parts used on oil rigs in the North Sea.

Problem

Risk analysis had shown installation of the wrong part, such as a fuse, could have catastrophic consequences. The danger was a maintenance engineer could fit an unmarked part that looked like the right one. The pressure to resume operation would be high as the cost of downtime is enormous.

Solution

Codeway tested printed sample labels on various candidate materials and supplied them for testing. Some were smaller than a postage stamp. The company conducted summer and winter trials on support vessels and rigs.

Some of the trial labels were stuck to railings on supply ships for over six months. Eventually the company was able to select the best performing material and adhesive.

Result

In this way a label became the final link in the North Sea safety chain from a supplier of advanced solutions to the oil and gas industry.

Risk avoidance

The Deepwater Horizon explosion claimed 11 lives, caused 17 injuries, and cost BP over $54 billion.

Related Applications

How to capture images of box contents as well as dimensions and weight.

Read More...

How a builders merchant capures ePoD data for orders, invoices and stock

Read More...

How a building supplies company cut delivery errors and increased productivity.

Read More...

How a manufacturer sequences left and right parts for JIT deliveries in assembly order

Read More...

How a car parts manufacturer uses barcode tracking to cut risks of error in despatch

Read More...

How a distributor introduced barcode picking for an inventory of 150,000 SKUs

Read More...

Why an infection prevention company barcodes products for cleaning endoscopes

Read More...

How intelligent labelling and mobile data help sequence deliveries to assembly plants

Read More...

How a growing company automated its WMS for a new carton distribution centre

Read More...

How a machinery manufacturer uses mobile terminals to pick spares for its global network

Read More...

Why a medical devices company installed real time tracking instead of an ERP upgrade.

Read More...

Why a sports distributor chose rugged Android mobiles to boost warehouse productivity

Read More...

Tracking the manufacture, installation and maintenance of a desert pipeline

Read More...

How labels became vital links in the North Sea safety chain after the Gulf of Mexico disaster

Read More...

How a grower of bedding plants automated labelling of packs for garden centres

Read More...