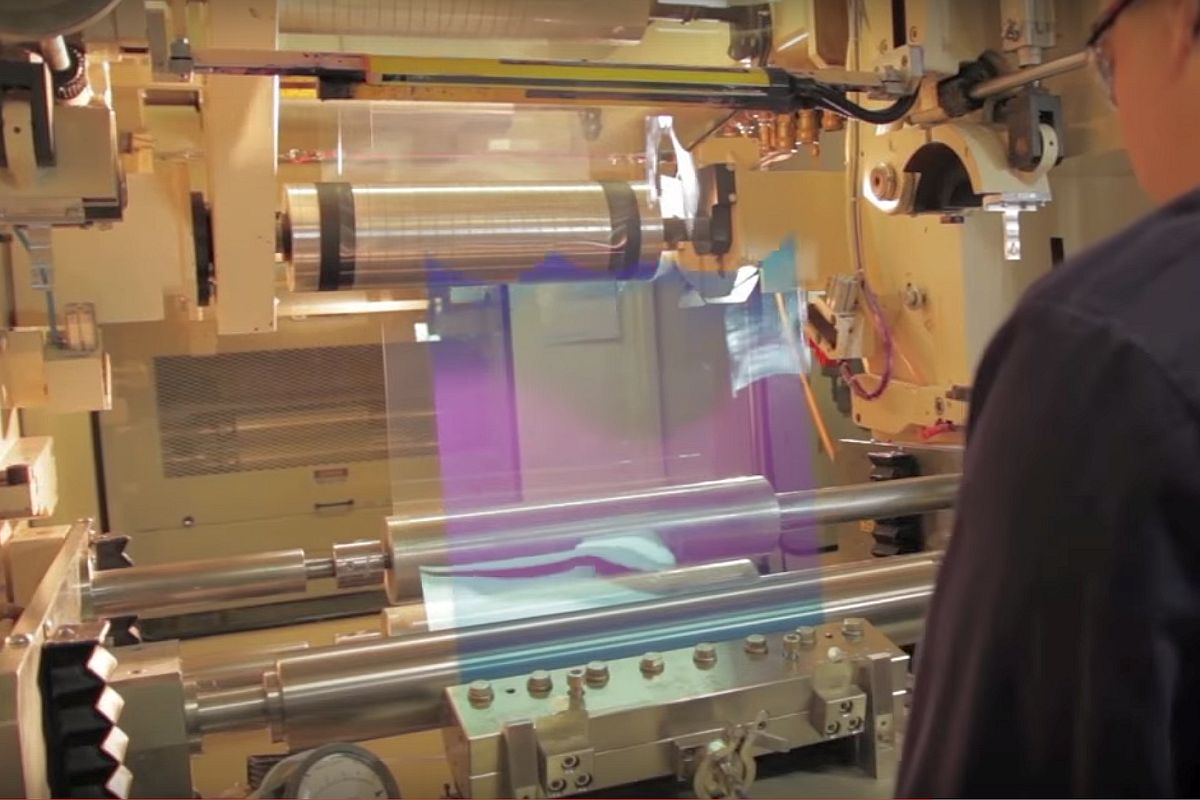

The company moulds precesion plastic parts with specialised coatings for many product manufacturers

A precision plastics moulder supplying automotive, medical and safety product manufacturers had difficulty in tracking hundreds of jobs in production. The results were delivery delays and excessive overtime pay.

The multi-stage process included optical coating, hand finishing and test.

Problems

- Tracking the location of work–in–process.

- Tracking the cost of the work–in–process inventory. Lack of real–time data capture was causing large discrepancies in inventory values.

- Tracking lot numbers of raw materials used in batches of customer parts.

- Tracking which machines and employees made the parts.

- Capturing data from the automated coating lines to complete the tracking and traceability record for each batch.

Solution

The company has a sophisticated ERP system for materials planning and for scheduling jobs. An automated interface passes jobs, routes and bills of material to BellHawk.

BellHawk tracks:

- Materials: receipt, put–away, consumption, production, picking, packing and shipping.

- Jobs: employee and equipment hours for each job step.

BellHawk returns material costs, labor hours and machine hours.

The ERP system computes the actual cost for each job and compares this to the planned cost.

Production PCs with corded and cordless scanners to capture data. Hands–free matrix scanners record of trays of materials at the entrance and exit tunnels to the automated coating lines.

The BellHawk DEX (automated data exchange) implements the interface between BellHawk and the ERP system.

The process control system uses DEX extensions: to pick up the coating recipe from the BellHawk database, and to send BellHawk tracking data on each tray of parts progressing along the automated line.

Results

- A real–time view of all inventory and work–in– process.

- Accurate cost data for work–in–process and finished goods batches.

- Sixfold expansion of the business in less than four years without adding personnel to manage and track manufacturing.

Related Applications

The Converting Operations Tracking and Traceability System is specifically designed for organizations that convert rolls and sheets of material into products.