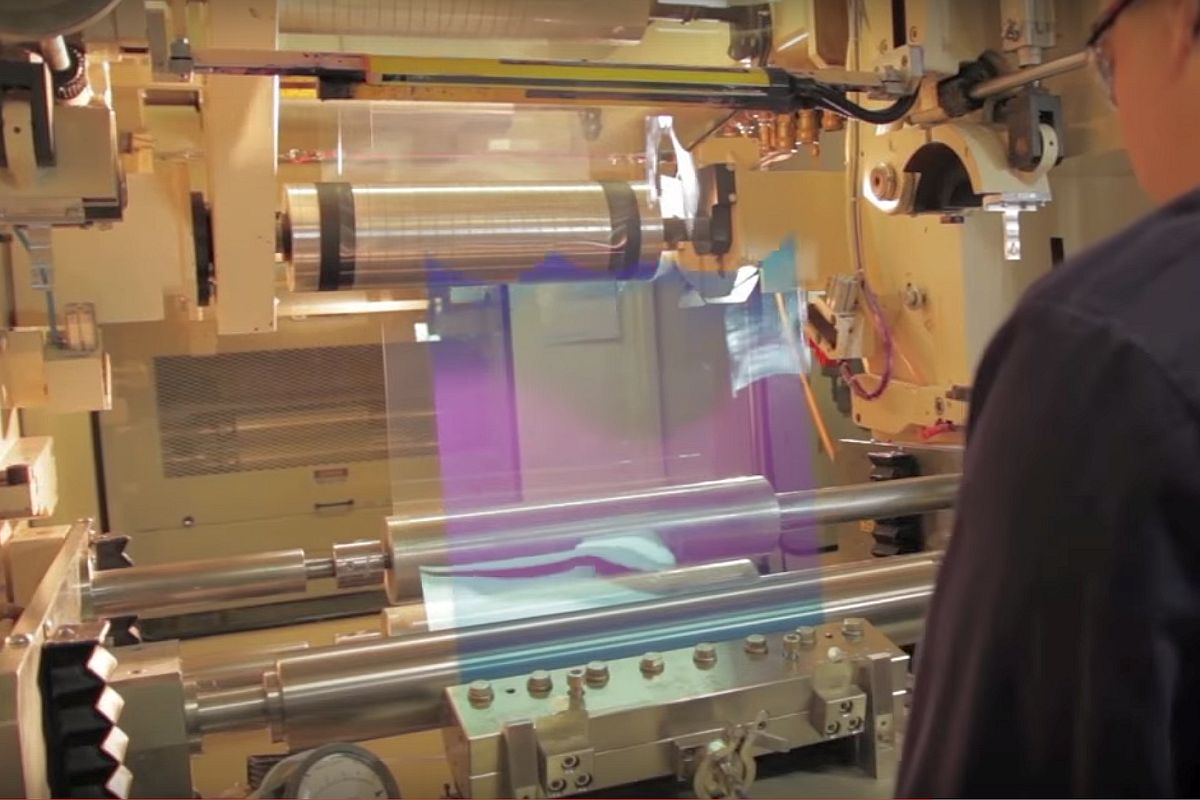

Customers want clearly identified rolls of paper and specify critical data to appear on the label. Image UPM Raflatac

This North American company is an integrated manufacturer of pulp and paper.

Through industry consolidation, the company had different manufacturing systems at its plants; each producing its own label formats. Two sales systems captured and hosted customer order information. These were completely separate from the manufacturing systems.

Business goal

The main business objective to deliver consistent labelling and improve customer service.

Requirements

Customer service

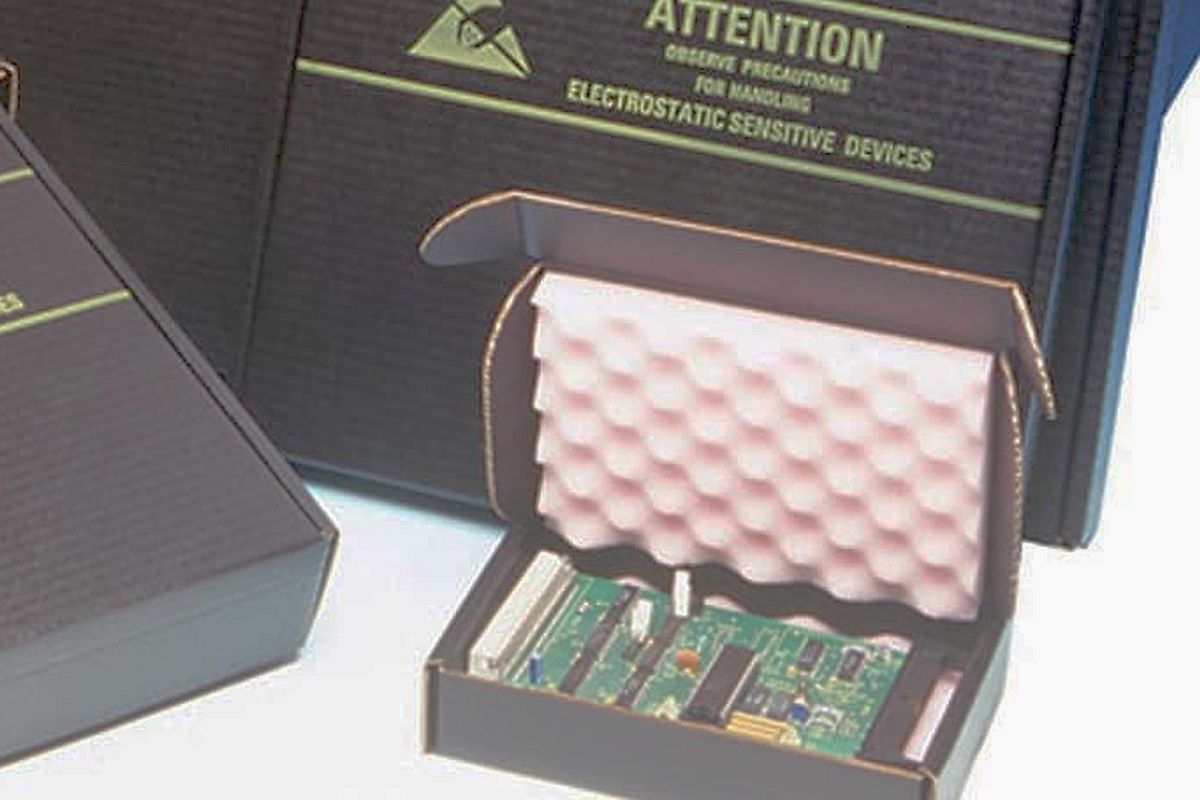

Some customers specified critical data for their labels. This information was captured in the sales system while the manufacturing system printed the labels. The company needed a way to ensure the information appeared on the label.

Branding

Customers received the same product with different labels from different plants.Consistent branding and labelling was needed.

Service levels

Labels had to be produced on automated machinery iin less than 15 seconds. A Wide Area Network (WAN) outage would be crippling. The company needed label printing software that was centrally hosted and always available locally at each site.

NiceLabel LMS solution

Seamless Integration

The company created business rules within NiceLabel to take in label data in various formats from its MES and sales systems. Customer specified label information is now available to the MES systems. When a roll or skid comes down the conveyor the LMS prints a label and a robot applies it.

Centralised Labelling

The company now has centralised label design, review and approval, and version control. 20 label templates with industry standard identifiers have replaced hundreds of old ones. Branding and sustainability certifications are in colour.

Streamlined Workflows

The company turns round label changes quickly. If there is a hardware failure, labelling shifts to a secondary machine to sustain steady production levels and business continuity.

Results

Top level customer service

Operational and supply chain delays have disappeared. Customers are delighted with the new labels.

Accuracy and agility

Now, products are sourced from various mill locations. Labels can be printed at different locations, regardless of where the product is manufactured. The company is able to exchange supply chain information with its customers..

More production uptime

Since implementing the NiceLabel solution has maintained a high level of 24x7 uptime and met its strict SLAs.

Related Applications

The Converting Operations Tracking and Traceability System is specifically designed for organizations that convert rolls and sheets of material into products.