What goes out?

What happens in between?

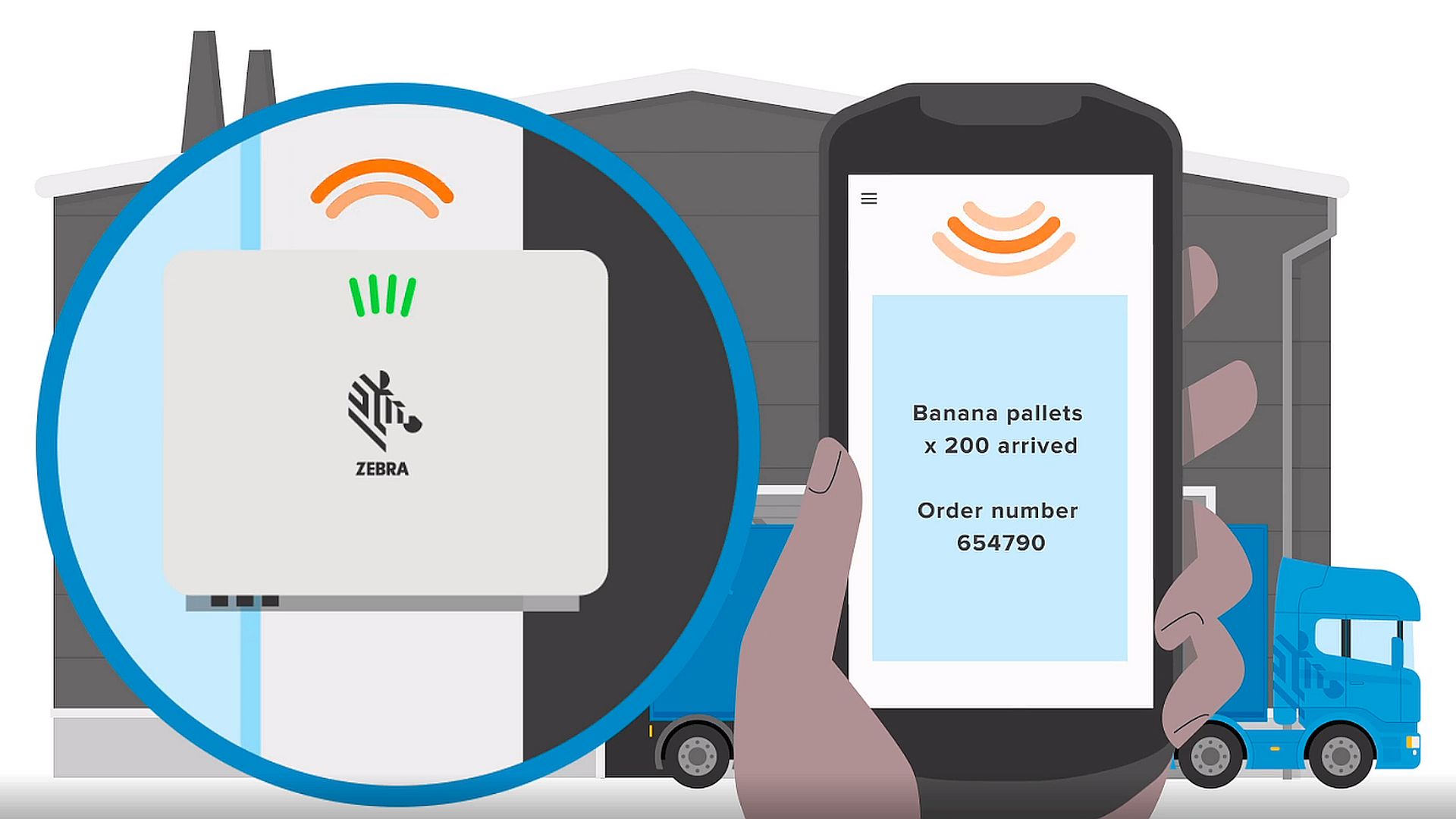

![]() Zebra has a wide portfolio of products. Codeway puts them to use in tracking systems.

Zebra has a wide portfolio of products. Codeway puts them to use in tracking systems.

Wherever you are on the Industry 4.0 journey, in manufacturing, warehousing and logistics, the basics are same tracking orders and the materials you need to fulfil them accurately on time. Identifying and scanning things with barcodes and rfid tags is a key part of the road map so why not make the most of them today. After all they avoid error (by checking what people are doing) and capture up to the minute data (so people can see what to do next).

Production

What comes in? Materials from the supplier (lorry at the top left of the graphic).

What goes out? Products to the customer (lorry at the bottom right of the graphic).

What happens in between:

- Goods in (handling receipts, ASNs, purchase orders, )

- Parts inventory (issuing BOM/Kanban materials)

- Manufacturing (making intermediates, producing WIP)

- Assembly (processing work orders)

- Quality (inspection, test, rework, scrap)

- Packing (compliance, customer orders, product registration)

- Goods out (picking, palletisation, staging, ASNs)

Supply chains depend on accurate data. The ASN a supplier generates at step 7 (Goods out) appears at to the customer at step 1 (Goods in). That's why people working towards Industry 4.0 say data comes before automation.

Codeway supplies label printers, scanners and mobile computers together with software for critical process or the operation as a whole.

Materials and operations tracking is most easily achievable with cloud software using tracking numbers for items and batches in (real or virtual) containers. Critical process software usually requires custom development (Codetrack). These systems are best introduced in stages and can be deployed at multiple locations.

Codetrack puts a barcode on every carton to control cross-docking, picking and despatch.

Codetrack puts a barcode on every carton to control cross-docking, picking and despatch.

Distribution

The pattern for distribution warehouses is similar though processes differ.

What comes in? Materials from the supplier (lorry at the top left of the graphic).

What goes out? Products to the customer (lorry at the bottom right of the graphic).

What happens in between:

- Receiving operations (ASNs, purchase orders, identification, labelling, QC, custom processes)

- Returns management ((RMAs, identification, labelling, QC, routing)

- Cross-docking (identification, match to shipping, orders, movement)

- Put-away (identification, location, movements)

- Picking operations (custom processes, location, identify item, identify container, labelling, exceptions) 6 Packing operations (identify items, match to order, print document, print label, route)

- Staging operations (identify, match to order, sequence items, kitting, exceptions, consolidate loads)

- Loading operations (sequence consignments to schedules, match containers to sequence, ASNs)

- Inventory management (real time reports, stock checks, expiry dates, scrap, ownership, reusable asset tracking)

Industrial warehouse and depot operations at single and multiple sites is achievable with cloud software using tracking numbers (BellHawk). Company specific warehouse operations usually require custom development (Codetrack). This means you can operate exactly as you want and, as our customers will tell you, remove constraints on growth.

Capture delivery data with Zebra mobile computers using wireless tags ot barcodes.

Capture delivery data with Zebra mobile computers using wireless tags ot barcodes.

Delivery

What comes in? Loading (lorry at the bottom right of the graphic).

What goes out? Delivery (lorry at the top left of the graphic).

What happens in between:

- Hub and depot (subset of warehouse operations)

- Transhipments (unloading, staging, loading)

- Delivery operations (ASNs, consignment/line item records, shortages, damages, returns, ePOD, store/forward)

- Service operations (ASN work items, task, items used, materials used, items retuned, notifications )

- Returns collections (RMA, items returned)

Specialised logistics

Some companies have logistics specialised needs. For instance, Codeway has supplied tracking and control systems for:

- Automotive parts

- Building materials

- Explosives

- International cargo

- Medical kits for treatment centres

- Pallets

- Vehicle inspection and deliveries

Systems

The systems Codeway provides (Codetrack, TraceNow, BellHawk) exchange data with logistics, stock and invoicing systems in real time. Zebra envisages the delivery of banana in the image above will be registered in a secure IOT distributed ledger, similar to Blockchain but without its costs.

- Desktop label printers: Zebra ZD421 • ZD621

- Ultra-rugged scanner with programmable keyboard and display: Zebra DS3600-KD

- Mobile computer: Zebra MC3300ax

- Touch computer: Zebra TC52ax

Contact us for information and pricing on Zebra products and services.