BellHawk Online Operations Management Option

Demand Driven MRP Planning (BOL-DRP)

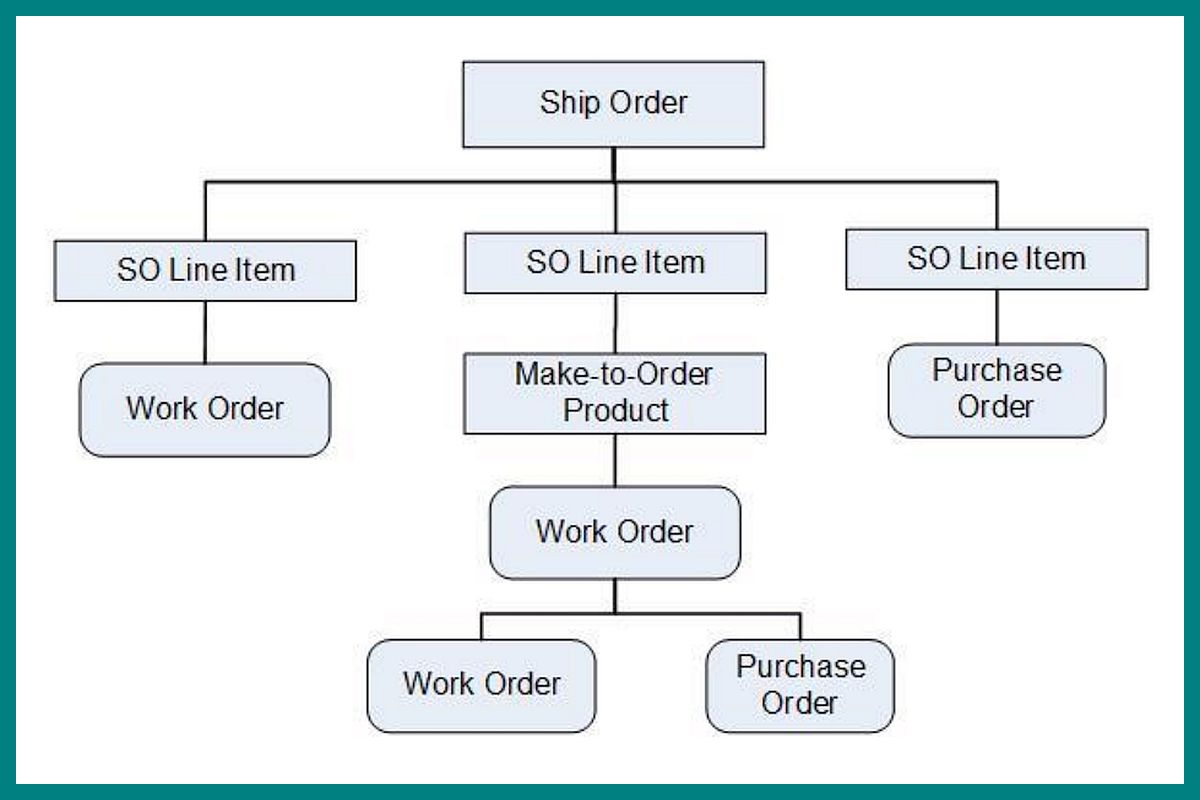

Demand Driven Planning works with Available Inventory Prediction to generate Purchase orders and Work Orders in response to customer Ship Orders.

Virtual inventory

Available Inventory Prediction tracks virtual inventory as well as physical inventory:

- On-order

- To be consumed on work orders

- To be made on work orders

- To be shipped to customers.

This gives managers a real-time view of what needs to be made or ordered to meet new customer orders.

Simplified issuing of purchase orders and work orders

Managers can issue work orders and purchase orders themselves. However this can involve copying details from customer orders and duplicate data entry. This is very tedious for an assembly with sub-assemblies and parts to be made or ordered.

DRP solves this problem by generating the purchase and work orders for each ship order line. The user has the option to create a work order order or issue a purchase order at each level. This goes on recursively until items to be purchased remain.

Advantages of DRP over conventional MRP systems::

- Demand driven.Each customer order is added to the plan as it occurs. No need to forecast of demand even if that were possible for make-to-order on demand..

- Manager controlled. An experienced manager decides what to make or buy. No modifications to make the MRP plan correspond with reality.

- Artificial intelligence.DRP is an advisory system with AI rules to automate routine tasks and guide the user. These rules are specific to the business. As an example the computer will recommend how much material to purchase but lets the manager apply his knowledge to the decision.

- Bills of Material Like an MRP system, DRP uses a bill-of-materials (BOM) for each assembly. But, unlike an MRP, computer aided design software can generate these BOMs after the customer order is received. The purchase and work orders can be created from this design data.

- Generic part numbers. Unlike conventional ERP systems BellHawk allows generic part numbers with options, such as size, colour and finishes, specified at customer order or design time. This leads on to generic BOMs with the options inherited by the sub-assemblies, components, and purchased parts. For this reason many make-to-order and semi-custom manufacturers find DRP much easier to use..

- Offcuts. BellHawk can track off-cuts by length and/or width. It includes these in the available inventory calculations for DRP. This avoids ordering or making more material when sufficient off-cuts are in stock.

BellHawk Online Data Sheet

Demand Drive Materials Resource Planning(DRP)

Requirements

Base system

Real-time Operations (RT-OPS)

Modules

Ship Order (SO)

Puchase Order (PO)

Available Inventory Prediction (AIP)