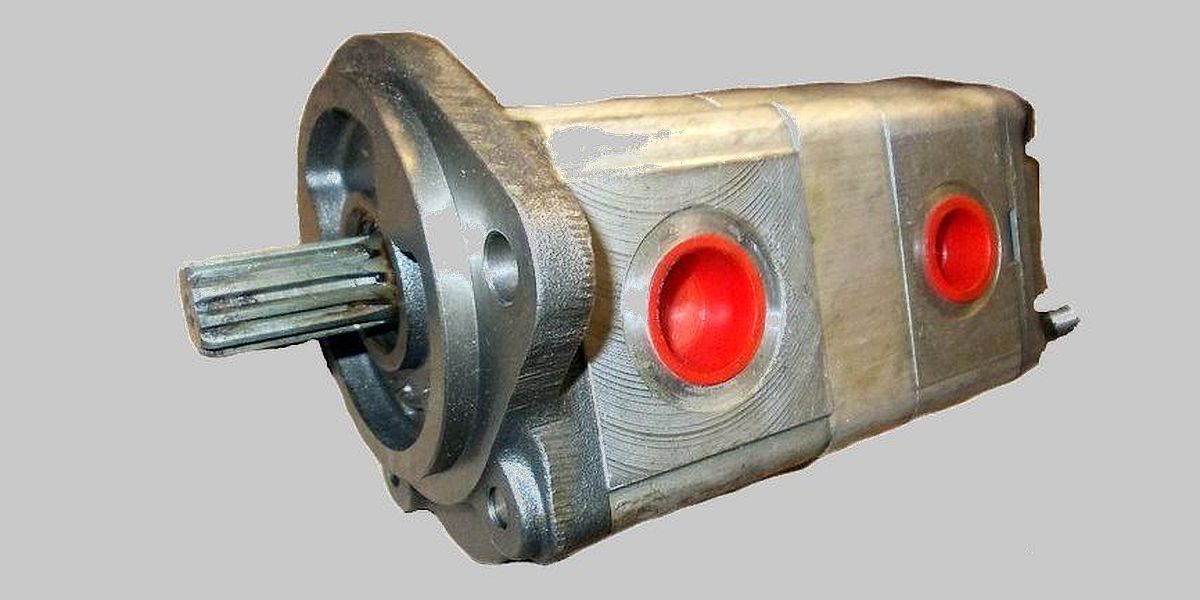

Machinery from Brasil to Singapore will stay out of commission if the right parts like this hydraulic pump do not arrive from England

Accurate fulfilment

This company, a long standing Codeway customer for printers and scanners, was reviewing standard WMS packages. None met the requirements for their international parts distribution operation. They mentioned their problem to an equipment supplier who knew Codeway had supplied a custom system to a local petfood distributor.

The problem

The company supplied parts to its distributors in many countries by air, road or sea. Some spares, such as batteries, could not go by air. To control transport costs on both sides the company shipped "economic" batches at intervals.

This arrangement worked well when deliveries were accurate. However there were many errors due to complications in the manual fulfilment process.

Distributors were sending several orders, and numerous changes, during the intervals before their next shipments. After each update the Oracle system issued a new release of the whole order.

The parts division picked the first release then picked and "unpicked" for each subsequent release. In some cases to expedite one despatch they borrowed parts from other "consignments in progress". These manual processes resulted in various errors.

The solution

After a day at the petfood distributor, the parts division saw they needed a flexible system to follow their processes.

The Codetrack system imports each release from Oracle, executes picks and unpicks to bring each consignment up to date, and returns the results with any exceptions to Oracle. It maintains a database of all stock movements.

Operators use the cameras in the mobile terminals to take images of the contents of each box and crate before they close them. Distributors check them before the goods are shipped to make sure the parts are what they expected. Mistaken identity used to be a problem.

Results

The system has simplified the procedure. The terrminals tell the operator what to do and check they have done it by scnning barcodes on the items and the packaging. Before the operators had to work things out for themselves and often made mistakes.

The status of each distributor's consignment is known in real-time. This provides for flexilbity in shipping.

The distributors report far fewer errors than before. Any losses during transit are much easier to identify.

PROCESS POINT SOLUTION

Problem Consignments are picked over time for shipment by sea; distributors change their orders and do not always select the right part.

ERP Oracle

Solution Implement picking and unpicking. Send the distributor a list and image each crate's contents to confirm before shipment.

Company Turnover: £50-100 million. Employees: 250-500

Corporation Turnover: $10-25 billion. Employees: 25,000-50,000

Related Applications

Automotive · Sequencing

Car body parts

Automotive Parts

Machinery Spares