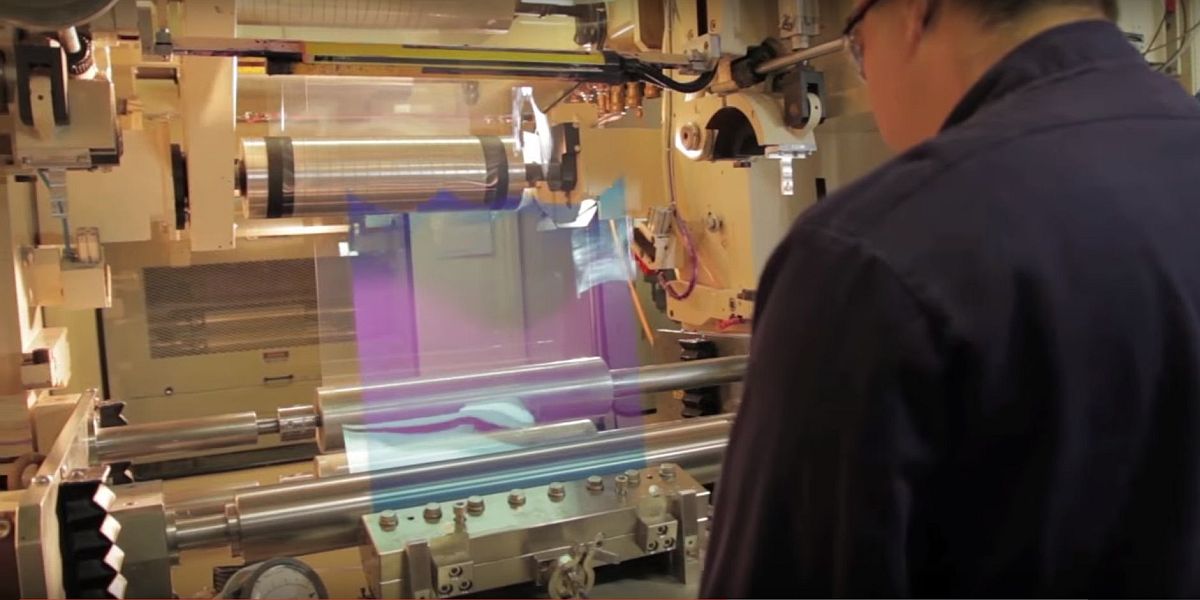

Jobs at the roll convertor in this article ran from a few hours to weeks. Image: Kodak Roll Conversion

This convertor coats large rolls of paper, plastic and aluminum foil to order in a wide variety of finishes. After coating, the rolls are slit. Some are sheeted and boxed.

The company had been hanging onto its heavily customised ERP system. The cost of replacing it was prohibitive. After discussions with BellHawk they decided to integrate they decides to integrate real time barcode tracking system with a new financial accounting system.

General requirements

The nature of their business dictated the major requirements for the new system:

Multiple units of measure.

The company purchased rolls of raw material in pounds, converted in linear feet in a web coating process and and sold it by the square measure or ream. A system able to convert between these units of measure was an absoluterequirement.

Widths

To handle a width attribute for the rolls. This was to avoid creating part numbers for each different width of material. The system had to be able to convert between length and weight based on the width of each individual roll.

Material tracking

To track inventory: raw material, work in progress, intermediate materials, and finished goods in real-time in a large facility.

Production Tracking

To track operations to transform the materials

Butt rolls

To track butt rolls for conversion later and minimise scrap.

Traceability

To maintain traceability between the materials used and the materials produced.

Specific reasons for selecting a BellHawk system and accounting software

-

The computers on which the company’s existing accounting and production tracking system was running had become obsolete and were no longer able to function reliably.

-

The need to reduce the time to take annual inventory. This activity had took at least two weeks, from December 15th to early January, due to the variety of inventory and storage in many locations in a large mill complex. This was causing major personnel issues as employees had to work through Christmas and New Year.

-

The need to accurately determine the cost of each job. This client has many repeat orders but is in a highly competitive industry with thin margins. By accurately tracking the job costs, the client expected to be able to bid jobs more effectively.

-

Cost. A custom solution would cost over $500,000. The price of BellHawk and the AccPac accounting software was around $50,000. Over the next two years the cost of customisation and support for these system was about $150,000.

The System

The system took about two months to initially install and set up in a training-room. User training and deployment then took about six months due to the large number of people working on three shifts.

- Vendor purchase orders are entered in AccPac and exported to BellHawk.

- Raw materials are received and put-away in BellHawk using mobile computers. Receipts data is exported to AccPac.

- Usage of materials, labour and machine time is recorded in BellHawk using PCs at each machine. This is reported to the Accounting system.

- Material movements are recorded in BellHawk using mobile computers.

- Shipment of materials is recorded using mobile computers. The shipments are exported to the AccPac accounting system as they occur.

Big Benefits

The immediate win was to cut the annual stock take from 14 days to 12 hours. The inventory manager sent BellHawk a note of thanks for her Christmas and New Year.

Management information

The company now has all the real time information it needs available to anyone with a PC.

Rapid retrieval of material

Mobile computers have enabled rapid putaway and retrieval of materials.

Profitable pricing

Sales people can look at the cost of previous jobs when bidding for new jobs or repeat orders. They no longer bid too high or do jobs for less than cost.