Pharmaceutical manufacturers must comply with stringent regulations requiring every aspect of labelling to be accurate and traceable.

One of the top European generic pharmaceutical manufacturers in Europe has production sites in five countries. Its distribution centres deliver medications to more than 70 countries.

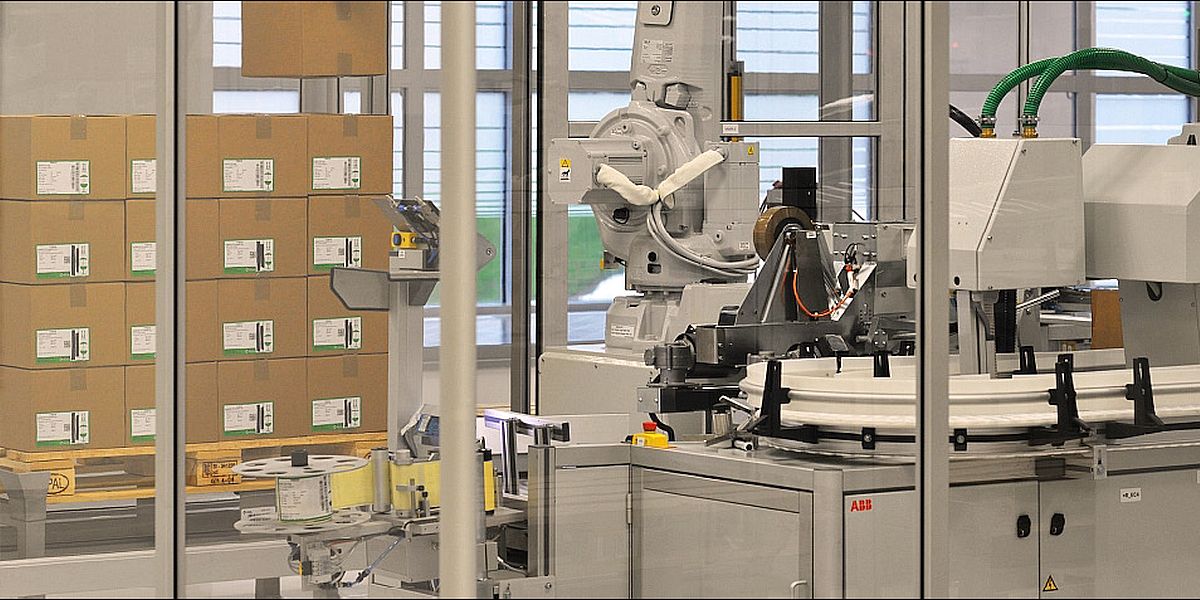

They were building a new state-of-the-art production facility. The company knew its labelling processes would not support future growth. The new facility was an opportunity to implement a modern label management system.

Project goals

- Unify labelling on a single platform,

- Better supervision of label variations

- Streamline regulatory compliance processes.

Requirements

Manage complex regulatory compliance

Stringent regulations in key markets included including documenting all new and updated label templates. All printed labels had to be archived for a year after tend of life of the product..The company had time consuming manual procedures to ensure compliane but they needed electronic label compliance system.

Unify labelling

The company had ended up with hundreds of hard coded label templates for SAP, their Werum MES the sites, and their labelling systems. Labels were inconsistent and label change requests took a long time as they depended on the It department.

Utilise master data for labelling

The company kept high standards for its master data and wanted to bring it label data up to the same level. They wanted a way to integrate label lifecycle management with their master data management system.

Reduce label variations

The catalogue of the company’s labels was fragmented. Management of revisions was complex and took up a lot of time. Thay wanted a manageable number of templates on centralised labelling platform.

LMS solution

Label lifecycle management system

The NiceLabel LMS enables the company to comply with FDA and GMP requirements. The electronic label design and approval process ensures data accuracy, cuts paperwork, and ewnables quick responses to customers' requirements. The system archives PDF copies of all printed labels.

A unified labelling platform

The company now uses NiceLabel LMS to manage all aspects of labelling. They use universal templates for printing labels regardless of the printer model and whether Werum or SAP triggered the task..

Electronic label catalog

The company can see all label data across the enterprise. Users can compare labels on their screens and highlight any differences.This helps them achieve high levels of quality control, label data accuracy and template consolidation.

Graphical label design interface

Business users who best understand the requirements design the labels. They no longer depend on IT.

Real-time integration with SAP and Werum

The company integrated with SAP and Werum using pre-built certified NiceLabel connectors,. The user-interface remained the same so print operators did not need additional training..

Results

- Streamlined compliance: the electronic label lifecycle management system saves the company countless man hours.

- Label consistency: the right label template is printed and the output is consistent across all systems at all locations.

- Template consolidation: the electronic catalogue has to find duplicate labels and reduce the number of templates to maintain.

- Business ownership of label layouts and content; business users at can now design and manage labels without the help of IT.

- Unification and scalability: all labelling is now integrated on a single platform which will scale for future growth.

- Supply chain: the company is extending labelling suppliers and sub-contractors to improve master data managemen and optimise inbound logistics.

Downloads

Related Applications

NiceLabel LMS

Bacterial Bioscience

NiceLabel LMS

Biologicals

NiceLabel LMS

Generic medicines

Animal Health

Veterinary Medicine