The labelling system gets the information customers want on their packaging labels from company's ERP system

The company manufactures biotechnology products and markets them through distributors. The factory was labelling about 1600 shipments daily. Most distributors have their own specifications for each label.

The warehouse was using its own systems for labelling and order processing as well as a warehouse management system and an enterprise resource planning system. Fast growth led the company to upgrade its IT infrastructure. They took the opportunity to standardise their labelling processes..

“We had approximately 12,000 Microsoft Word documents stored on a file/print server. These documents contained all of the various labels we used for our customers. We had over 30 different label sizes, so nothing was standardised.” IT Manager.

The problem

Packers printed labels from Microsoft Word.:

- Look the customer up in the order processing system

- Find the correct label for customer's order

- Open the label

- Populate it with correct information

- Adjust the printer to handle the layout

- Print the label.

This process wasted over 50 man hours a day. "We estimated that it took 1-2 minutes to find the labels they needed for each order. That’s not including the time it would take to change the label size or adjust the printer. And this process had to be repeated for each customer,” IT manager.

Insecure Microsoft Word templates

People modified the label templates manually. Problems arose due to keying error and inadvertent changes.

“The risk of errors was very high because you could edit the text in the label. We had a lot of errors because of the wrong lot number, an incorrect barcode or because the article text had been overwritten. All of these things were at risk because the template wasn’t locked.” IT Manager.

No quality control

The quality management team's primary focus was on materials. The customer was often the one who detected the error. The cost of relabelling 10-15 shipments per month was unsustainable.

No traceability

No printed label history meant there was no traceability of labels shipped in case of a recall or a complaint. There was no control process for label change requests.

NiceLabel LMS processes comply with FDA and GMP rules for record keeping and register label data for traceability

Business goals

The IT Department decided to find a label management solution to integrate with their existing WMS and ERP systems.

Their goals were to:

- Eliminate errors

- Reduce printing time

- Increase label quality

NiceLabel LMS solution

- The company uses the Designer to create labels.

- They use templates to standardise formats and information.

- All information is stored in a secure database.

- They use the NiceLabel Document Management System (DMS) to process change requests, approve formats and deploy them to production..

- Users now have a print button in the WMS to send label information to NiceLabel Automation.

- The Automation module merges the data with the label layout and prints the label. Users do not have anything else to do.

"We estimate that we have saved between 20-30 hours per week with the NiceLabel solution" IT Manager

Results

- Reduced labelling errors from 10-15 per month to zero.

- Reduced time to select and print a label from 1-2 minutes or more to 10 seconds.

- Reduced 12,000 Word documents to 50 NiceLabel templates

- Reduced 30 label types down to 3 sizes.

Customisation

"We have a lot of different types of information in our ERP system. Customers want to have individual text and item numbers, and for this NiceLabel is absolutely perfect" IT Manager

Downloads

Related Applications

Ophthalmology

Artificial Lenses

NiceLabel LMS

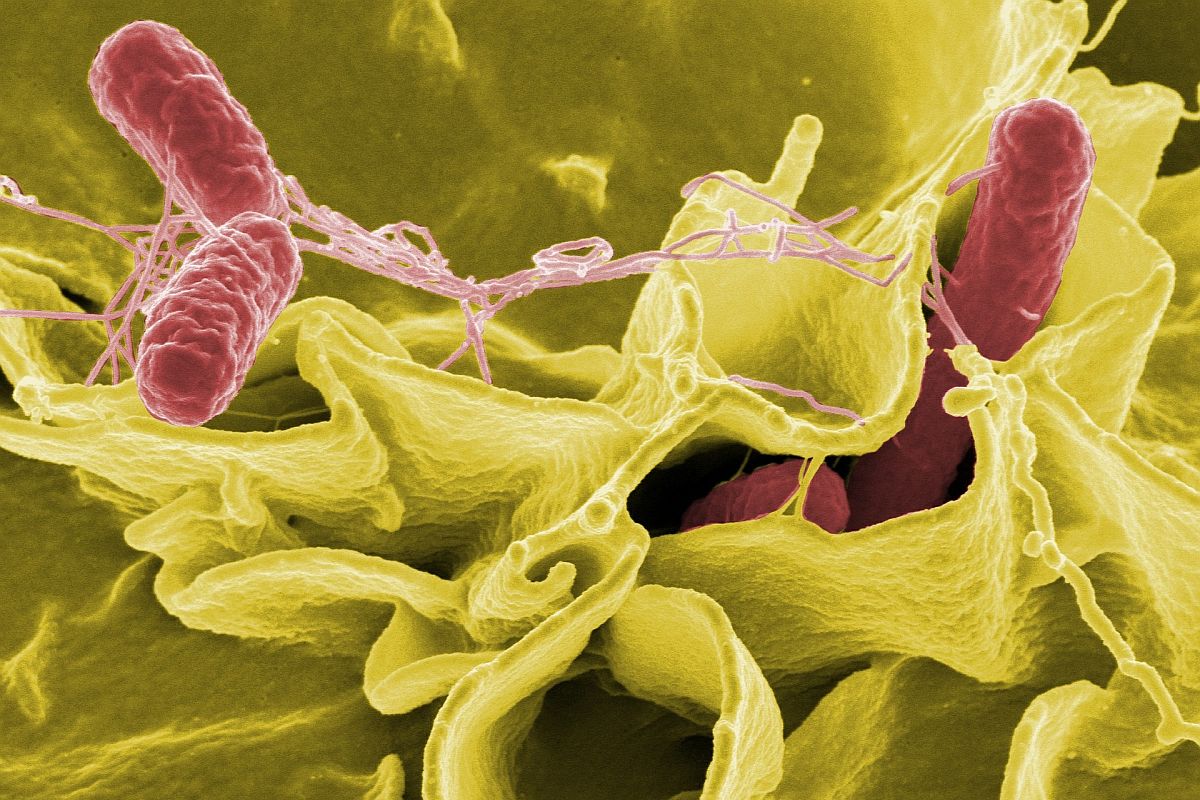

Bacterial Bioscience

E-commerce

Bag Labelling

NiceLabel LMS

Biologicals

NiceLabel LMS

Biotech Factory

Consumables

Bottled Fluids