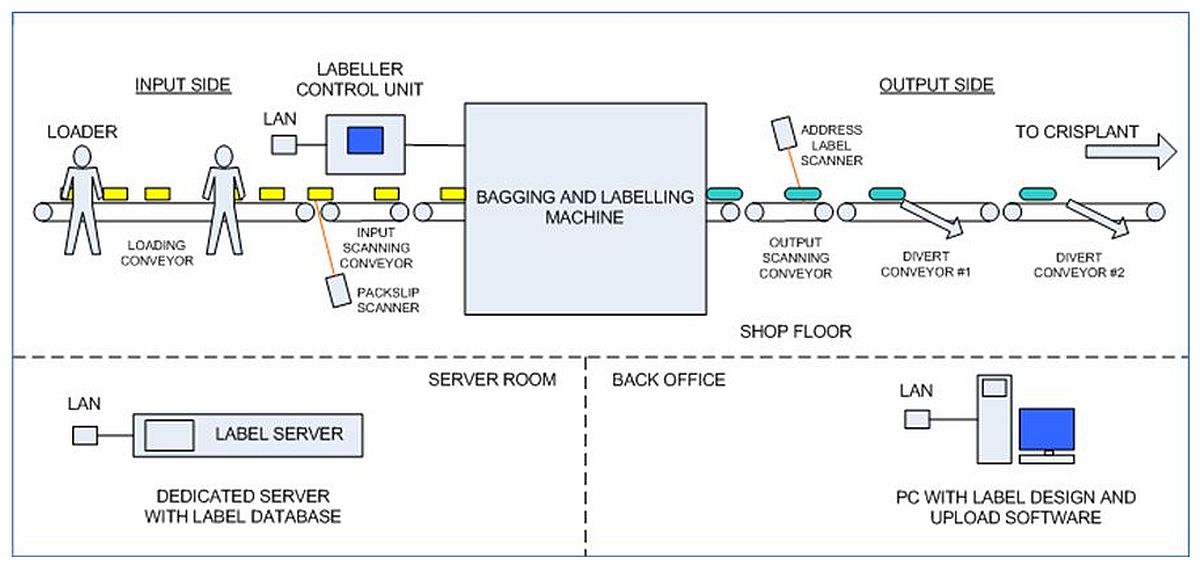

The Codeway system controls conveyors, scans items, feeds them for bagging, prints and applies bag labels and routs the bags

Productivity in the bag

This multi-channel company receives about 20,000 single item orders every day. They decided to install a dedicated line to bag and label them.

The supplier of the automated bagging machine had worked with Codeway before and asked us to join them on this project.

Conveying · Bagging · Labelling · Routing

The company picks single item orders in bulk and prints packslips by product. Loaders place a packslip and its item on a conveyor. The Codetrack system scan the packslip, feeds the item into the bagging machines, prints and applies a carrier label, then scans this label to route the bag to the main sorter, special distribution, or a reject bin if the barcode on the label does not scan.

Process

The Codetrack system controls conveyors, scanned items before bagging, printed and applied bag labels, and routed the bags

When the item arrives at the end of the loading conveyor Codetrack measures its length and height as it scans the packslip. Codetrack looks up the order details, selects the carrier label. It paces the items into the machine according to their dimensions which determine the bagging cycle time.

The Codetrack labeller prints the bag label and applies it to the bag film at the start of the cycle. The labeller has a special high capacity label roll unwind mechanism to minimise roll changes.

After bag leaves the bagging machine, a scanner reads the address label. Codetrack decides whether to activate either of the two diverters or deliver the bag to the sortation system.

Codetrack returns data to the company's order processing system. It maintains a detaled log of all events on the line for traceability and troubleshooting.

Results

Productivity:

The Codetrack pacing mechanism increased throughput over standard bagging rates by over 25%.

Reliability

During a site visit the operators said downtime due to the labelling and scanning was insignificant.

Flexibility

There are many carrier label templates. Codetrack has an embedded version of NiceLabel for the company to make changes and add new ones.

Related Applications

Ophthalmology

Artificial Lenses

E-commerce

Bag Labelling

Tracking

Beer Kegs

NiceLabel LMS

Biologicals

NiceLabel LMS

Biotech Factory

Consumables

Bottled Fluids

Imaging · Dimensioning

Box Clever

Proof of Delivery

Building materials

Scheduled collection

Christmas Turkey

BellHawk Food

Food Processing

BellHawk Food

Food Traceability