BellHawk Online

Powerful, pay as you go, easy to use barcode tracking

Food Manufacture

The BellHawk Online Food Manufacturing System is a low-cost and easy-to-use system that enables food, beverage, nutritional supplement and veterinary product manufacturers to meet EU/FDA and HAACP requirements for tracking the conversion of ingredients into finished products.

Food Manufacturing System (FMS) is intended for organizations that transform ingredients into food or veterinary products and need to comply with FDA materials tracking and traceability requirements. FMS consists of the Real-Time Operations Tracking System (RT-OPS) plus the Warehouse Management (WMS), materials traceability (TRACE) and the Quality Control (QC) modules. It is especially suited to food, natural supplement, and biologic substance processors who are seeking an affordable track and trace solution.

The BellHawk Online Food Manufacturing System (BH-FMS) is a low-cost and easy-to-use system that enables Food, Beverage, Nutritional Supplement, and Veterinary product manufacturers to meet EU/FDA and HAACP requirements for tracking the conversion of ingredients into finished products.

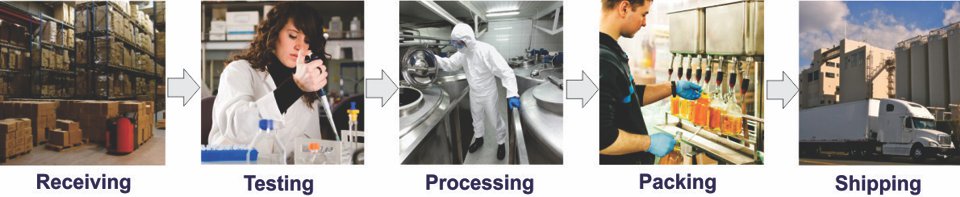

BellHawk FMS makes extensive use of barcode technology to track materials from receiving, through put away, processing into intermediate products, packing into finished products and finally the picking, packing and shipping of finished products. It can also track and enforce quality assurance testing for raw, intermediate, and finished goods.

BellHawk FMS provides managers, supervisors, and customer service people with a real-time view of inventory, production operations, and customer order status. It can also track materials and their transformation in many different units of measure.

BellHawk FMS replaces the use of paper forms and manual keyboard with barcode scanning by material handlers and line operators. This not only saves the time of many people but also enables the system to prevent expensive mistakes by providing real-time point-of-action warnings before, and not after, mistakes are made. This includes preventing mistakes such as using ingredients that are contaminated or have not passed quality inspection.

BellHawk FMS captures all the data required for tracking and traceability compliance in a computer database so that it can quickly be accessed to provide the one-step-forward and one-step-backward recall data as required by the Food Safety Modernization Act of 2011, the FDA, USDA, HAACP, and similar requirements.

BellHawk FMS enables organizations to comply with requirements from large retail and restaurant chain organizations for electronic traceability with rapid recall capabilities. This includes performing mock-recalls at a push of a button.

As well as tracking raw, intermediate and finished materials, FMS tracks work-in-process materials. BellHawk also tracks who worked on each operation of each work order and what equipment was used as well as what quality control tests were performed and their outcome.

FMS can also store formulas and bills of materials and use these to prevent mistakes in using the wrong materials for making intermediate and final products. FMS can also help ensure that the correct packaging is used.

FMS tracks lot numbers as well the expiration date and quality control status of each container of material or serialized item. It uses this data to warn operators when they are about to use materials that are past their expiration date or failed quality inspection. BellHawk can also use this data to help prevent the mixing of lots when needed.

With the BellHawk Online warehouse management system (WMS) option, FMS can import purchase orders (POs) from ERP or accounting systems and track the receipt and put-away of raw materials against these POs. It can also import customer orders and use these to generate pick orders for picking and shipping the finished products as well as generating work orders to make products to order.

With the optional BellHawk Barcode Label Printing System (BPLS), FMS can print GS1 compliant SSCC labels to go on cartons and pallets of product so as to enable their tracking in the supply chain.

FMS captures Advanced Shipment Notice (ASN) data, which can be relayed to customers using third-party Cloud-based EDI systems. BellHawk Online also supports interfaces that enable automated data exchange with ERP and accounting systems.

Related Applications

Ophthalmology

Artificial Lenses

E-commerce

Bag Labelling

Tracking

Beer Kegs

NiceLabel LMS

Food Labels

BellHawk Food

Food Processing

BellHawk Food

Food Traceability

Retail Distribution

Global traceability

Food Labelling

Haggis

NiceLabel PowerForms

Inflight Meals

Fresh Food

Prepared Vegetables

Explosives

Product Serialisation

Animal Feed

Sack Labelling