Explosives

Labelling and tracking explosive items at all levels of packaging with unique 2D codes

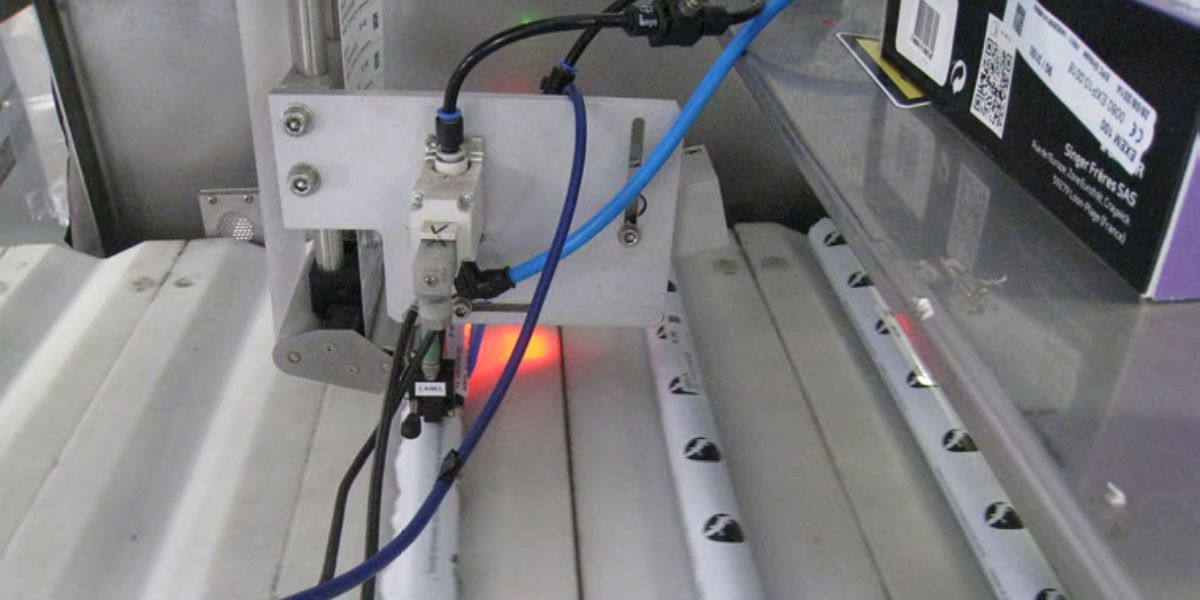

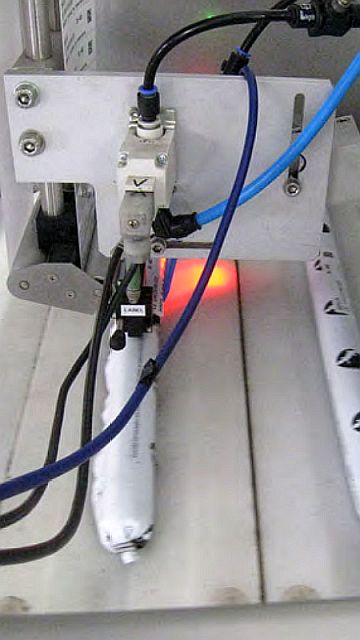

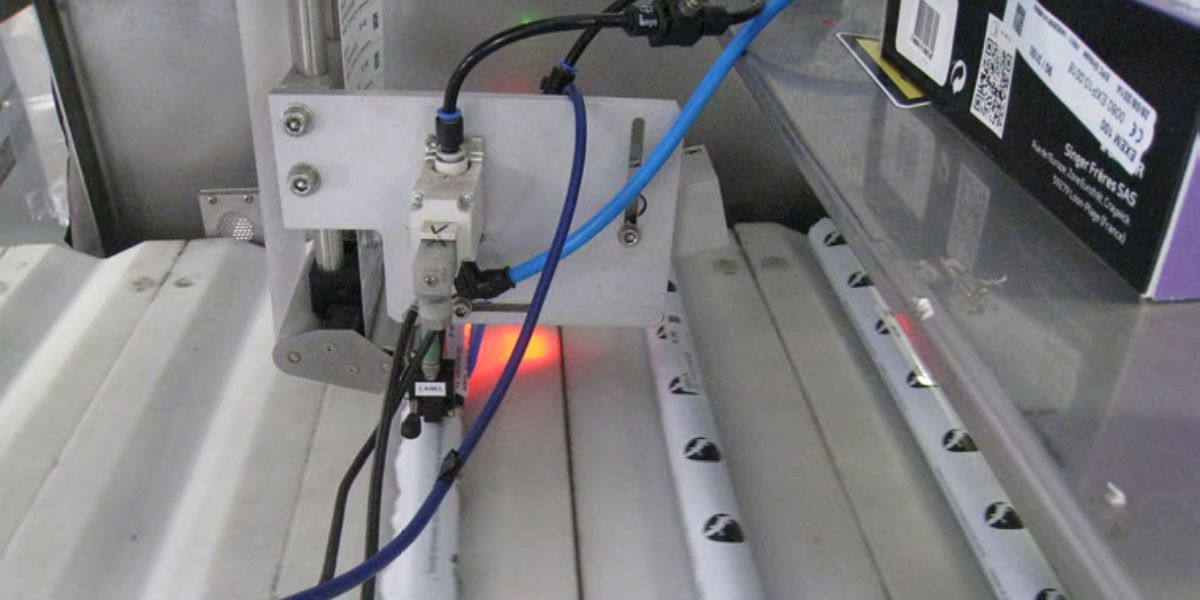

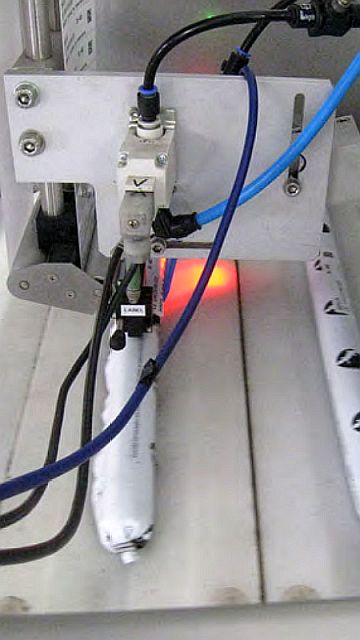

Up to 120 cartridges per minute pass under the labelling and scanning head from left to right towards the boxing station

Item and case registration for 100% traceability

The Codetrack product serialisation system prints and applies unique number labels to every item and pack. Packaging levels include bag, inner pack, outer pack and pallet. The system registers the unique numbers in a database with product attributes and production data for traceability. Codetrack records movements using fixed and mobile scanners.

Tracking

For explosives like cartridges and detonators, typical movements are from production line to a magazine, from magazine to a depot, and from depot to the end user such as a quarry. When products are shipped from one location to another Codetrack generates ASN documents (XML files) containing a structured list of all the unique numbers in the consignment.

Cartridge identification

Each cartridge is labelled, scanned and counted into a case. The cartridge is rejected if the scan fails. Codetrack keeps a record of the unique numbers on the cartridges in the case.

Case identification

When the case has the specified number of cartridges, it is released onto a conveyor. A printer applicator labels the front of the case. A scanner records the unique case number or sends a reject signal. The Codetrack serialisation system registers the case number and the cartridges numbers in the tracking database. It holds the cartridge numbers in rejected case for rectification.

Pallet identification

Pallets are identified in a similar way to cases. When the specified number of cases have been scanned on to a pallet, Codetrack prints a label for manual or automatic application. The system allows for full and partial pallets.

Related Applications

How a supplier introduced barcodes to improve picking and reduce risk at eye clinics

Read More...

How a rubber moulder tracks materials to avoid parts failure on the road

Read More...

Print apply labelling integrated with order tracking, picking, scanning, bagging, and sorting

Read More...

How a brewery uses barcodes to staunched keg losses and automate traceability

Read More...

Label management system assures compliance in vaccine identification and packaging

Read More...

Labelling takes seconds with 50 templates. It took minutes with 12,000 Word documents.

Read More...

Barcode tracking, automated labelling, expiry date control, and hazardous material logs

Read More...

How a business machinery company identifies bottles on its fluid consumables filling line

Read More...

How to capture images of box contents as well as dimensions and weight.

Read More...

Tracking materials used in the manufacture of cables by length and weight

Read More...

How six smart templates replaced thousands of local language labels

Read More...

How a large group realised its vision for a single solution for labelling and marking

Read More...

How integrating labelling with production and compliance cut risk and cost

Read More...

How a manufacturer introduced non-stop tandem labellers to its continuous filling line

Read More...

How an egg packer promotes its products with clear packaging and colour labels

Read More...

Why an infection prevention company barcodes products for cleaning endoscopes

Read More...

How centralised group label management paid for itself in four months

Read More...

How Label Cloud enables suppliers to deliver good ready labelled for sale.

Read More...

Front-face labelling of multipack flour bags with GS1 outer pack labels for Waitrose

Read More...

Easy to use, to track ingredients to products and meet EU/FDA and HAACP requirements

Read More...

Why a cooking oil blender uses a barcode tracking system for its packaged products

Read More...

How barcode tracking can avoid expensive mistakes and achieve real-time traceability

Read More...

How a BellHawk materials and operations tracking system provides real time traceability

Read More...

How intelligent labelling and mobile data help sequence deliveries to assembly plants

Read More...

Label management benefits a generics producer at its new plant and existing sites

Read More...

Streamlined labelling meets the challenge of global compliance regulations

Read More...

How a carrier of a famous British brand to global outlets achieved 100% traceability

Read More...