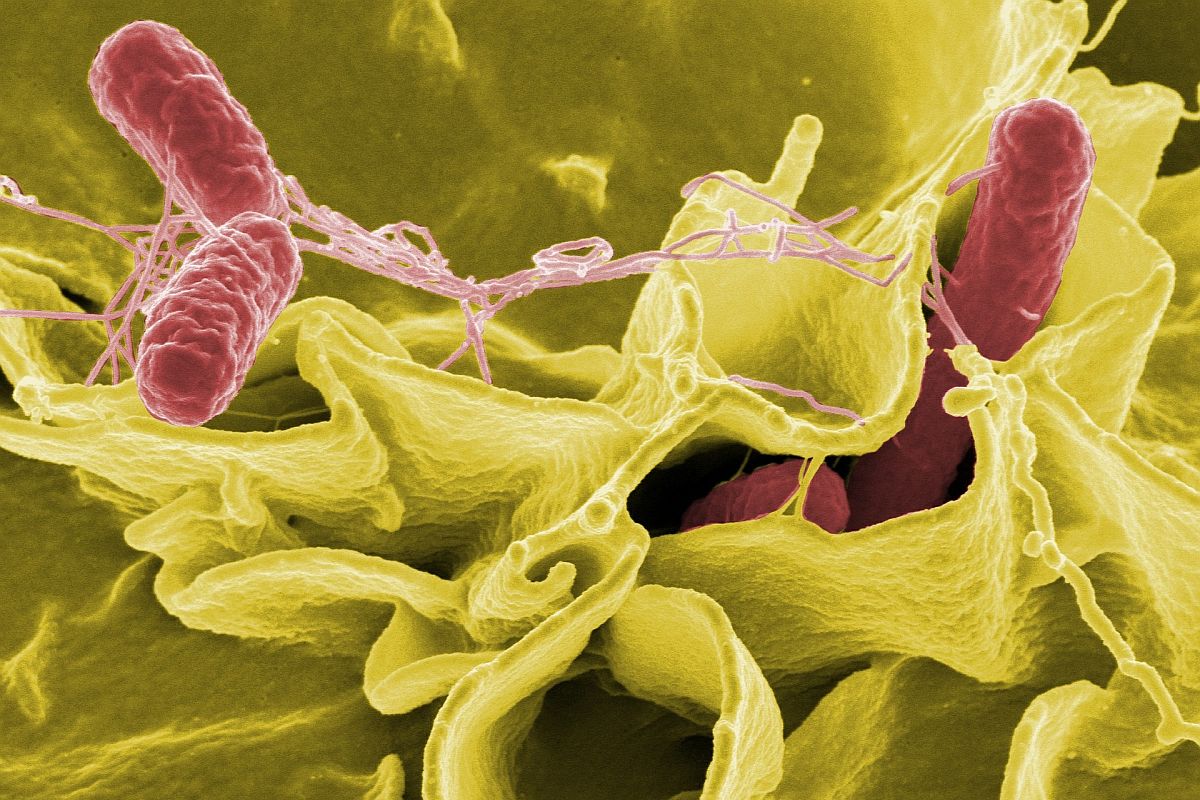

The public expect all food and drinks to be traceable and safe. Image: EFSA

Food traceabilioty is a prime application for a BellHawk tracking system is food traceability.

It will track what comes in, what goes out, and what happens in between. A key press will trace one step back to suppliers and one step forward to your customers.

Overview

To track and trace ingredients and products BellHawk identifies every batch and container with a unique number. This is usually a barcode, sometimes an RFID tag.

The system stores this data into a form suitable for performing mock and real recalls. and stored in a history database.

At the same the system warns users when they are about to make a mistake, such as mixing an expired ingredient or using the wrong packaging material. This prevents expensive mistakes.

Tracking

The system tracks the status and use of every container and batch of ingredients and product from end to end:

- The receipt and put away of each container of material from suppliers by lot number and expiration date.

- The quality assurance status of raw materials and ingredients to ensure no quarantined material are used for production. batches.

- Which employees and machines performed each step of processing, packaging and distribution.

- Each container of product mix, its quality control inspection, and its subsequent use in packaging different products.

- Picking, packing and shipping of the finished products.

Traceability

Tracking operates in realtime. It captures the complete history of each container of ingredients, each pallet of packaging materials, and each batch of product including shipping to customers. Product defects due to operator error or machine malfunction can be included in the tracking and traceability process.

BellHawk provides one step back ingredient tracking and one step forward product recall data.

As the system is browser based, information can be made available at anytime to anyone. This can include compliance staff at distributors and retailers.

Real-time business intelligence

The traceability database provides up to the minute operational informtion:

- Customer support: product and order status.

- Materials managers: inventory

- Production managers: work-in-process and finished product.

- Accounting: accurate cost data for intermediate and finished products.

Related Applications

Ophthalmology

Artificial Lenses

E-commerce

Bag Labelling

Tracking

Beer Kegs

NiceLabel LMS

Food Labels

BellHawk Food

Food Processing

BellHawk Food

Food Traceability

Retail Distribution

Global traceability

Food Labelling

Haggis

NiceLabel PowerForms

Inflight Meals

Fresh Food

Prepared Vegetables

Explosives

Product Serialisation

Animal Feed

Sack Labelling