The law requires quarries and other users to store explosives in magazines and track every item by its unique number

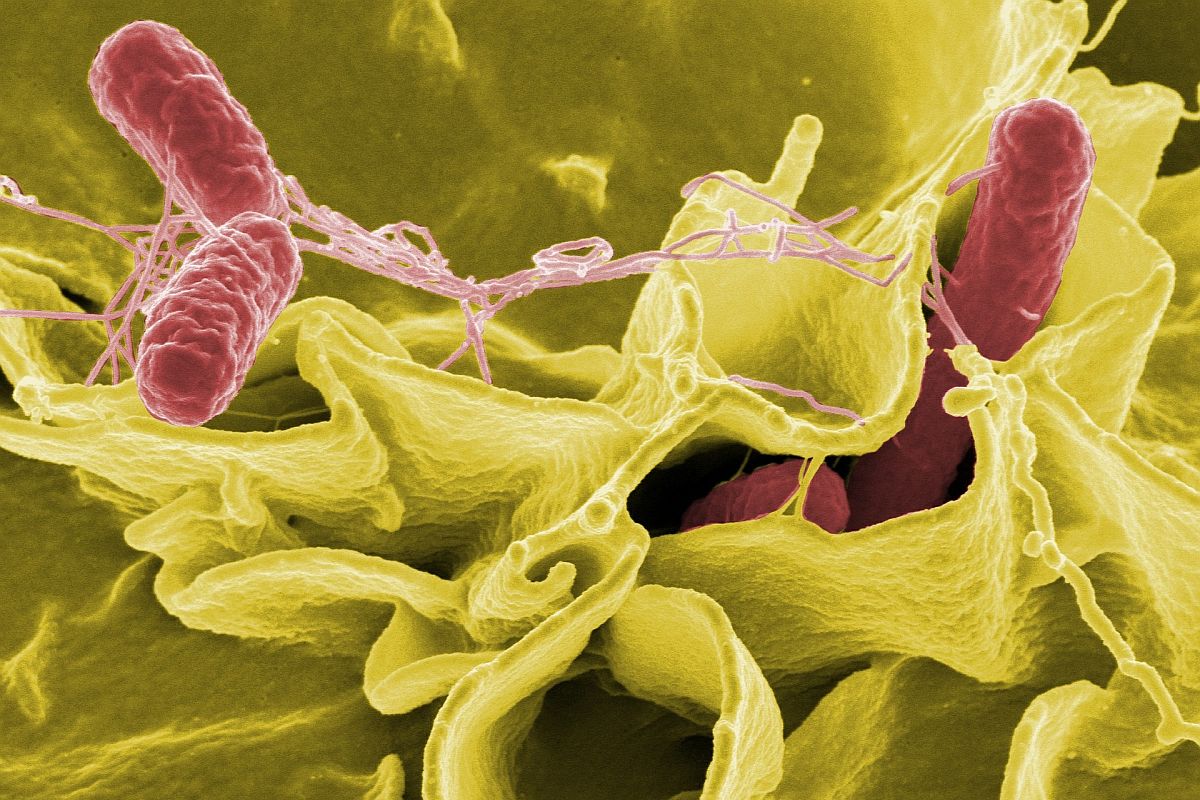

Bombings in Madrid

On 11 March 2004 terrorists bombed four trains in Madrid killing 193 commuters and injuring 2,000. Spanish miners had sold the explosives. The European Commission determined strict control of the civil explosives supply chain was necessary and issued a directive four years later.

The EU directive

This directive required all civil explosives and their packaging carry unique numbers. Manufacturers, distributors and users were to track the location of these items from points of manufacture and importation to the points of use. These explosives are used in the main for quarrying, demolition and extraction of oil and gas from the North Sea.

The Federation of European Explosives Manufacturers (FEEM) published guidelines for coding and data exchange in 2009. The industry agreed to mark items with Data Matrix 2D codes following GS1 standards. Suppliers would send their customers advanced shipping notices as XML files containing a nested list of the pack and item numbers.

Everyone in the chain was expected to scan the Data Matrix codes on the outer packaging to track their movemnt from one location to the next . This was a major change for the industry. The Commission eventually agreed identification by manufacturers be operational from April 2013 and tracking to the point of consumption by April 2015.

A manufacturer who had helped to draft the FEEM guidelines asked Codeway to implement them.

Identification

Overall the group had about a dozen manual, semi-automatic and automatic lines producing detonators, cartridges, sacks and other types of explosive product.

The Codetrack production system for each line runs one or two industrial PCs. This presents a standard interface for job control and monitoring progress (items, bags, boxes). A specific plug-in controls labelling and scanning (single and multiple devices) as well as interfacing with scales and PLCs. The controller records the numbers of the items produced and registers them in the Codetrack database when a network link is available.

To reduce risk explosives production areas are separated from each other on large sites and the manufacturer could not justify networking some small units. For these line we provided a controller running on a handheld computers. Operators use these to scan items with pre-printed labels into bags and boxes.

Codetrack was installed on all lines before the EU deadline in 2013.

Tracking

An operator uses a handheld computer to scan each box at the end of the production and transfer it to a location in a magazine. The handheld computers operate in batch mode as there is no WiFi in the magazines. To ensure the 'explosive quantity' is within the official limit for the magazine the handheld computer have a record of every item it contains.

The configuration of boxes of explosives are subject to strict control and official approval. However mixed boxes of detonators are allowed to meet the requirements of quarry 'blasting plans'. Codetrack provides for picking into 'ad hoc' mixed boxes using the handheld computers.

Quarries often change their blasting plans before explosives are loaded onto the truck for delivery to site. Codetrack provides virtual staging locations for these sites allowing for picking and unpicking the changes. When the load is confirmed Codetrack generates the XML file for transmission to the customer.

Codetrack provides a complete history of any item from manufacture to despatch from a depot or to a delivery location when drivers have handheld computers.

Many users import these XML files into the TTE SaaS system. Companies across Europe handling explosives use this system to comply with the EU directive. In particular to hold records fror 10 years and to provide the authorities with the last known location of any item identified by its unique number.

Other applications

This Codetrack system will identify and track any serialised products that are bagged, boxed, palletised and consigned.

Related Applications

Ophthalmology

Artificial Lenses

E-commerce

Bag Labelling

Tracking

Beer Kegs

Imaging · Dimensioning

Box Clever

Proof of Delivery

Building materials

Multi-channel distribution

Building supplies

Automotive · Sequencing

Car body parts

Automotive parts

Despatch Verification

Specialist parts distribution

Device Parts

BellHawk Food

Food Traceability

Automotive parts

Fuel systems

Wholesale Distribution

Garments

Retail Distribution

Global traceability

Automotive Parts

Machinery Spares

BellHawk Stock Tracking

Medical Supplies

Retail Distribution

Mobile Selection

BellHawk Track & Trace

Oil Pipes

Identification Labels

Oil rig safety chain

Explosives

Product Serialisation

BellHawk Manufacturing

Roll Material Conversion

Animal Feed

Sack Labelling