When a part fails the correct replacement must be fitted. How do you identify it? Without a label you can't.

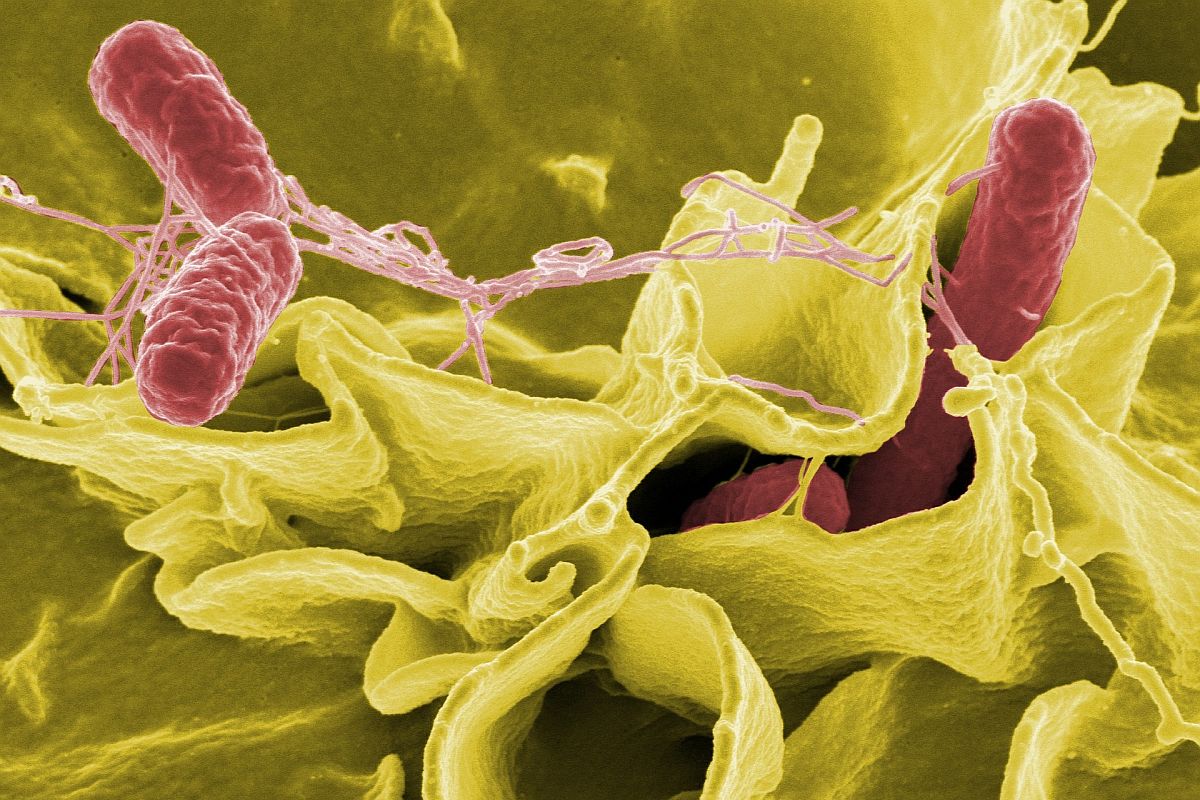

Explosion in the Gulf of Mexico

The Deepwater Horizon explosion on 20 April 2010 led to a root and branch review of safety systems in the oil industry.

In 2012 a leading global supplier of critical control and safety solutions contacted Codeway. Already a customer, they wanted system to print highly durable identification labels for parts used on oil rigs in the North Sea.

Problem

Risk analysis had shown installation of the wrong part, such as a fuse, could have catastrophic consequences. The danger was a maintenance engineer could fit an unmarked part that looked like the right one. The pressure to resume operation would be high as the cost of downtime is enormous.

Solution

Codeway tested printed sample labels on various candidate materials and supplied them for testing. Some were smaller than a postage stamp. The company conducted summer and winter trials on support vessels and rigs.

Some of the trial labels were stuck to railings on supply ships for over six months. Eventually the company was able to select the best performing material and adhesive.

Result

In this way a label became the final link in the North Sea safety chain from a supplier of advanced solutions to the oil and gas industry.

Risk avoidance

The Deepwater Horizon explosion claimed 11 lives, caused 17 injuries, and cost BP over $54 billion.

PROCESS POINT SOLUTION

Problem Risk of fitting the wrong part due to misidentification or no identification

Solution Durable labels printed by thermal transfer, tested for months on rigs and supply vessels

System Supplier Turnover: $5-10 billion. Employees: 10,000-25,000

User Turnover: £100-250 billion. Employees: 50,000-100,000

Related Applications

Imaging · Dimensioning

Box Clever

Proof of Delivery

Building materials

Multi-channel distribution

Building supplies

Automotive · Sequencing

Car body parts

Automotive parts

Despatch Verification

Specialist parts distribution

Device Parts

Mass Customisation

Item Verification

Automotive Parts

Machinery Spares

Seasonal Products

Made in advance

BellHawk Stock Tracking

Medical Supplies

Retail Distribution

Mobile Selection

BellHawk Track & Trace

Oil Pipes

Identification Labels

Oil rig safety chain

Horticulture

Plant Trays

Fresh Food

Prepared Vegetables

BellHawk Manufacturing

Roll Material Conversion

Animal Feed

Sack Labelling

Organic Compounds

Sample Tracking

TTE Explosives

TTE Track & Trace